DUAL BOX SNAKE WRAP PALLETIZER

MODEL PAL/07

Description:

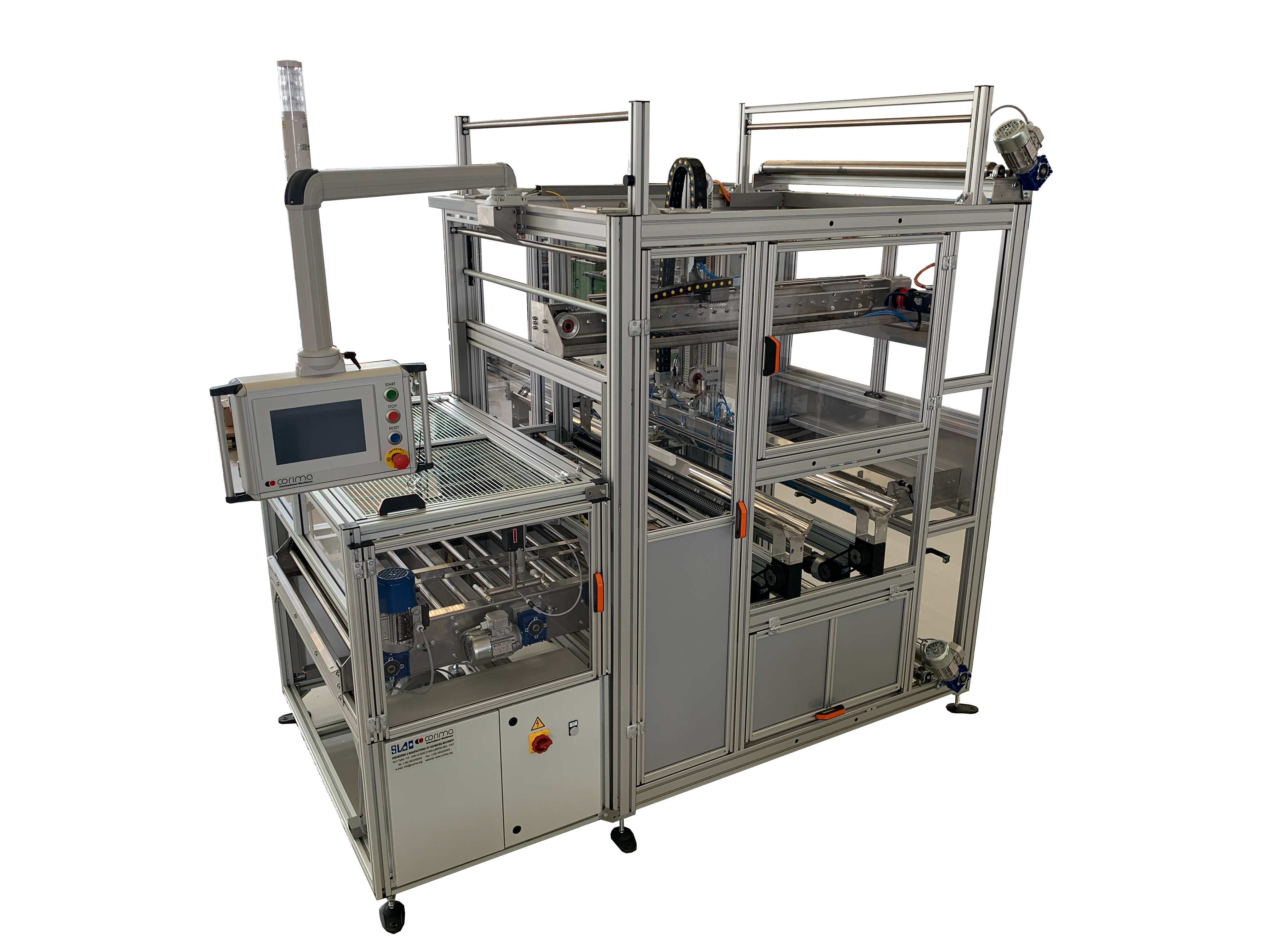

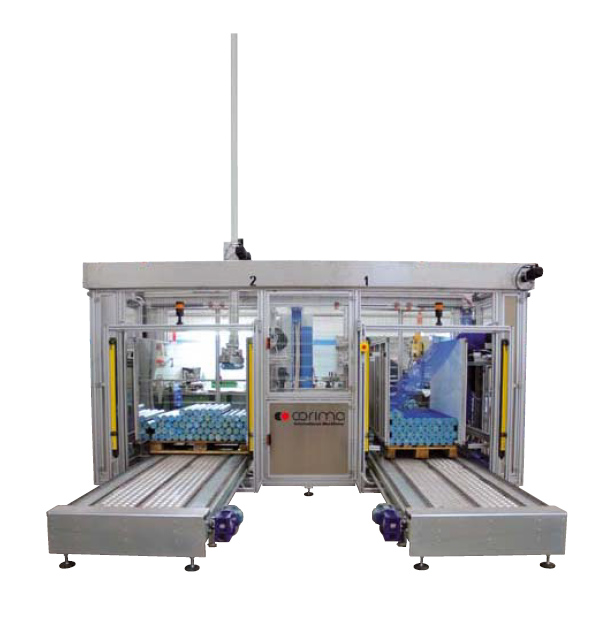

This machine has been developed by CORIMA to automatically palletize pre-made sleeves of ends applying a paper or plastic “snake wrap” between the layers to form a tight and secure pallet load.

The sleeves are carried by a conveyor into the machine. Here, the sleeves are picked up by the pick & place unit and placed on the pallet where the same unit handles the paper or plastic roll to form the desired snake pattern.

When the first pallet is completed, the p&p unit starts to form a new pallet load at the second work station while the first full pallet is transferred out of the machine by a motorized chain conveyor.

Technical data:

END TYPE standard sanitary ends, easy open ends, aerosol bottoms and domes,

general line components

END DIMENSION ø 52 mm (200) to 153 mm (603)

STICK LENGTH up to 800 mm

OUTPUT up to 6 pallets/minute

ELECTRICAL REQUIREMENTS 10 kW, 380 V, 50 Hz, 3-phase + neutral wire

AIR CONSUMPTION 200 l/minute at 6 bar (average)

Upon request the machine can be customized according to customer specifications

“A network of companies with acquired experience and know-how”